Corridor Technology, which specialises in advanced rail, road and energy infrastructure inspections powered by artificial intelligence, has been selected for a fully funded trial of its automated rail-corridor gauging technology for Network Rail.

The trial has been awarded as a result of a Small Business Research Initiative (SBRI) competition in conjunction with Network Rail.

The SBRI programme is delivered by Innovate UK and brings together government challenges and ideas from business to create innovative solutions. Innovate UK is part of UK Research and Innovation (UKRI), the national funding agency investing in science and research in the UK.

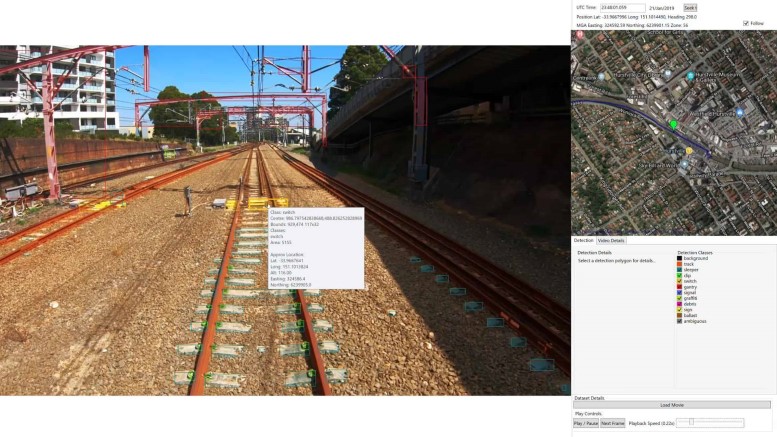

Network Rail brought to SBRI the problem of accurate gauging – measuring the location and encroachment of vegetation and masonry on rail networks. Corridor Technology, which originated in New South Wales, Australia, and is now a wholly owned subsidiary of the London-based Maestrano Group, will automatically analyse digital point-cloud data captured by Network Rail using LiDAR sensors mounted on its trains.

The analysis will be carried out using Corridor Technology’s cloud-based machine learning platform – developed and already successfully applied on Australian and Japanese railways.

Maestrano vice-president of sales Nick Smith said: “This project will enable Network Rail to benefit from our mature core technology. We will undertake the R&D required on top of our existing platform to create a bespoke application for them, working alongside Network Rail staff and their advisors to develop, test and demonstrate the modifications needed to meet their requirements.

“This project should expedite commercial implementation so that Network Rail can benefit from radically quicker processing times to obtain actionable and timely gauging information.

“Automating gauging data processing should also improve rail workers’ safety, by reducing the need for (and frequency of) boots-on-the-tracks inspections, and improve flexibility for train operators and other Network Rail customers (and therefore railway passengers and freight users) by enabling faster and more accurate scenario testing.”

Be the first to comment