VolkerFitzpatrick has been contracted to build the new Tyne and Wear Metro depot at Gosforth, near Regent Centre Metro station and within walking distance of Newcastle Freeman Hospital.

The contract was placed by Swiss train manufacturer Stadler, which is building the Metro’s new fleet of trains, due to enter service in 2023, and has a contract to service and maintain the new trains for 35 years.

The new purpose-built depot, which represents an investment of £70 million, will be built on the site of the current South Gosforth depot. Built in 1923, South Gosforth has been the home of the Tyne & Wear Metro fleet since 1980.

The project will involve the safe demolition of the old depot, clearing the site, followed by re-building the new depot. Work is scheduled to begin later in the year, with most of the building work set to be completed by 2025.

Work will be undertaken in stages, to enable the legacy fleet to continue operating from the depot while the construction work takes place. In addition, a temporary depot is being constructed at Howden to accommodate both the old fleet and to take in some of the new trains while the capacity of South Gosforth is reduced due to the building works.

The new will be depot will be designed to ensure maximum availability and reliability of the fleet, will vastly improve the working environment and become home to a wide range of activities, including preventative and corrective maintenance, overhauls and train presentation. There will be storage for spare parts and material supplies and office space for training and other support functions.

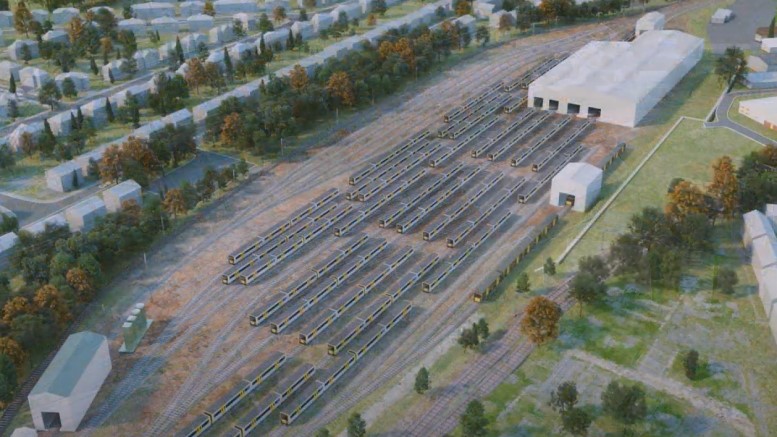

The 12-acre site will include the maintenance depot itself, as well as storage for spare parts and material supplies and office space for training and other support functions.

There will also be a wheel lathe, to restore the trains’ wheel profiles without having to remove wheelsets from the trains, and a wash-plant to clean train exteriors and other dedicated areas for both daily and periodic deep-cleaning.

The outside area will be adapted to optimise train movements and provide stabling for the new trains, while keeping noise to a minimum for the benefit of local residents.

The building will make best use of natural light, and all workspaces will have windows. Energy efficient lighting will be installed throughout the premises and solar panels on the roof will reduce overall energy consumption. Water recycled on site and rainwater will be harvested and used for train washing facilities and toilets. There will be a dedicated, secure area for bikes, and showers will be provided for people cycling to and from work.

Tobyn Hughes, managing director of Transport North East, said: “This investment in a new depot will revolutionise our maintenance facilities, creating a modern and energy efficient home for the new train fleet.

It’s a development that will secure the long-term future of the Metro system and deliver a step-change in quality for our workforce.”

Paul Lilley, VolkerFitzpatrick’s operations director, added: “We are delighted to have been appointed by Stadler to design and develop this new £70m facility.

“As a leading constructor of rail depots, we have extensive experience of managing such projects and look forward to helping Nexus further enhance their network and create a state-of-the-art facility in readiness for their fleet of METRO trains being introduced in 2024.

“Working in collaboration with Stadler, Nexus, other key stakeholders and our supply chain, we aim to demonstrate a one team approach for delivering this project, with sustainability and innovation at the forefront of the design, which will change the current landscape and bring a focal point to the local area.”

Robert Baxter, Stadler Rail Service UK managing director, commented: “The appointment of VolkerFitzpatrick to re-build Gosforth depot is a highly significant milestone for the Nexus project, heralding the start of this exciting project in the north east, which will see the transformation of rail travel in the region.

“Stadler has pledged to support the regional economy and involve as many Tyne and Wear-based companies in the project as possible. We are keen to use local suppliers for materials and services required for the depot re-build, the manufacturing of the new trains and the ongoing service and maintenance of the trains on the patch.”

Be the first to comment